14th November 2014

Boiler News

In the last newsletter, investigative work to the firebox of Boscastle's boiler was discussed, and I am pleased to report that this work has now started. Before describing the work so far, it is worth giving a little history about boiler No. 1315.

This boiler was built at the Southern Railways Brighton works in March 1947. It was first fitted to new Battle of Britain locomotive, 229 Squadron, then in 1953 to West Country Axminster and finally in 1959 to Boscastle, this being the fourth boiler our loco has had. Throughout its time in revenue earning service it had numerous repairs, major work being carried out in 1953 when new steel plate patches were fitted to the complete bottom half of the inner firebox. By the time of this heavy repair, the boiler had travelled some 223,251 miles and has since provided steam power for a further 527,000 miles until its current overhaul.

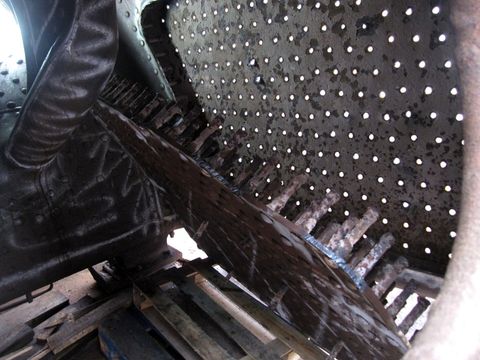

As you can see, the boiler has done an awful lot of work since its last major repair and not only are the original patches life expired, but so is much of the plate work above them. After seeking much advice, we made the decision to remove the inner right hand firebox side to a point above the brick arch position. The sides had been identified in the boiler reports as requiring renewal, and by removing this side we are also able to assess the condition of the inside face of the outer firebox.

Removing boiler plate is not easy - the fabric of a loco boiler is designed to be very strong and steam tight, and not to be dismantled.

The process is as follows; firstly you cut off all of the outer stay ends, grind them all flat and then mark the centres. Each stay end has to be drilled in increasing sizes at least three times, to remove enough material to allow the main part of the stay to be broken off without damaging the screw threads in the plate. Once all of the stays have been drilled and the inside plate cut away from its surroundings, a large pneumatic punch is used to break off all the stays from the outside, allowing the inside plate to fall away with the majority of each stay still attached to it.

The inside plate has proven to be in poor condition, justifying its removal and confirming the findings of previous boiler reports. The outer plate (despite the cracks identified in the NDT survey) is in much better condition, so shouldn’t need large sections removing. Armed with the information gained, we can now finalise a repair plan for the boiler and in the meantime, remove the corresponding left hand side plate.

There is some major surgery to carry out on the boiler and it is almost certain that we will find further work that we hadn’t anticipated, but this situation is not unique to Boscastle. Most Bulleid owners have either had this work done or are having it done, and had BR continued to operate steam, these locomotives would probably have had replacement fireboxes fitted

16th September 2014

This shows one of the new valve liners set on the horizontal milling machine, which is being used to cut the steam ports out. The ports are the row of holes around each liner, through which superheated steam passes into the cylinder and exhaust steam passes out. In the photo, holes are being drilled around the inside of each port position.

18th September 2014

While another loco was having some inspection work carried out, we took the opportunity to use the contractor (thereby lessening the cost!) to thickness-test Boscastle's main steam pipes. Here is the smaller of the three pipes which takes steam from the superheater header to the middle cylinder. The thickness has been tested and marked, in white, at points all over the pipe. The results were better than anticipated and all three pipes are fit for re-use, with minimal work required.

7th October 2014

This is a view of the rear of the left hand running plate with all of the associated components trial fitted. Underneath the running plate, the completed copper pipework can be seen running alongside the vacuum pipe. Above the running plate, the drain cock actuating (control) valve can be seen connected to its copper pipework, and set at an angle above that is the reverser drive shaft. This connects the reverser handle gear in the cab with the reverser screw mechanism under the running plate.

7th October 2014

In this view of the completed valve liners, the port holes can be clearly seen. Once the holes had been machined, a good deal of hand work was required to finish them and smooth any sharp edges. The liners are ready for fitting to the middle cylinder once a little preparatory work has been carried out.

3rd November 2014

This shows six of the twelve tender brake block holders. New bushes have been machined and fitted to all, with over half of them now painted. Most locomotives have a cast iron brake block which is drilled and held directly to the brake hanger with a pin, which if tight or rusted, can be difficult to remove when the block needs changing.

On a Bulleid loco, the block holder is pinned to the hanger and a smaller cast iron brake block is attached to the block holder with a long thin wedge. When the brake blocks are due to be changed, the wedge is easily removed to release the worn block. Similarly, new blocks are also easier and lighter to fit than a conventional brake block; the new component is put into place, the wedge dropped in and then tapped into place. No fiddling with filthy split pins and washers!

3rd November 2014

Three of our volunteers have spent many hours stripping and cleaning the 24 marker lamps for the loco and tender. To showcase their efforts and spruce up the front of the loco, three of the lamps were fitted for the GCR Auntumn gala. These will be removed for safe storage until they can be permanently fitted.

Images on this page are copyright A.J.Morgan, M.Playle